The regulations on hydrocarbons are sometimes complex and we invite you to refer to them carefully before undertaking a road transport operation. The purpose of this presentation is to provide you with a summary of the issue.

The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR), done at Geneva on 30 September 1957 under the auspices of the United Nations Economic Commission for Europe, entered into force on 29 January 1968. The Agreement itself was amended by the Protocol amending article 14, paragraph 3, done at New York on 21 August 1975, which entered into force on 19 April 1985.

To date, 52 countries are contracting parties to the agreement.

In France, the decree of 29 May 2009, known as the “TMD decree” (Transport de Matière Dangereuse), updated on 1 January 2022, relating to the transport of dangerous goods by land, imposes the application of the ADR on the national territory, and adds additional rules for all transport and also for national transport only

It replaces the decree of 5 December 1996 on the transport of dangerous goods by road, which in turn replaced the former RTMDR regulation.

Private individuals may in certain cases be exempted, within the limits specified in §1.1.3.1.a of the ADR:

a) the carriage of dangerous goods by private individuals where the goods in question are packaged for retail sale and are intended for their personal or domestic use or for their leisure or sporting activities, provided that measures are taken to prevent any leakage of contents under normal conditions of carriage. Where these goods are flammable liquids carried in refillable receptacles filled by, or for, a private individual, the total quantity shall not exceed 60 litres per receptacle and 240 litres per transport unit. Dangerous goods in IBCs, large packagings or tanks are not considered to be packaged for retail sale;

Professionals whose main activity is not the transport of dangerous goods may in certain cases be exempted, within the limits specified in § 1.1.3.1.c of the ADR:

c) For carriage by enterprises as an incidental to their main activity, such as supply to or return from building or civil engineering sites, or for measurement, repair and maintenance work, in quantities not exceeding 450 litres per packaging, including IBCs and large packagings, nor the maximum total quantities specified in 1.1.3.6. Measures shall be taken to prevent leakage under normal conditions of transport. These exemptions do not apply to Class 7.

The carriage undertaken by such enterprises for their external or internal supply or distribution is not, however, affected by this exemption

a. Definition

Our trailers are equipped with tanks that are IBCs according to the ADR.

Intermediate Bulk Container (IBC) is a rigid or flexible transportable packaging other than those specified in Chapter 6.1 of the ADR

a) a capacity:

- Not exceeding 3 m³, for solid and liquid substances of packing groups II and III;

- Not exceeding 1.5 m3 , for solid substances of packing group I packed in flexible, rigid plastics, composite, fibreboard or wooden IBCs;

- Not exceeding 3 m3 , for solids of packing group I packed in metal IBCs;

- Not exceeding 3 m3 for Class 7 radioactive material;

b) designed for mechanical handling:

c) able to withstand the stresses generated during handling and transport, which shall be confirmed by the tests specified in Chapter 6.5 of the ADR ;

According to the ADR, our full tank is a package:

“Package” means the end product of the packing operation ready for shipment, consisting of the packaging or large packaging or the IBC itself with its contents. The term includes gas receptacles as defined in this section as well as articles which, because of their size, mass or configuration, may be carried unpackaged or in cradles, crates or handling devices. Except for the carriage of radioactive material, the term does not apply to goods carried in bulk or to substances carried in tanks;

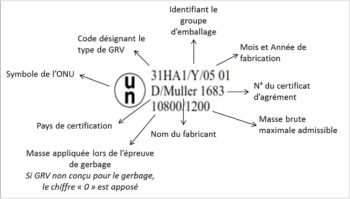

b. IBC approval marking

Each design type of IBC used for the transport of dangerous goods shall be constructed in accordance with specific requirements and shall be capable of passing a series of tests carried out by the competent authority in accordance with Chapter 6.5 of ADR.

If the IBC design type passes these tests, the competent authority shall issue an approval mark which shall be affixed to an identification plate welded to the body of the container. Such a marking shall take the following form

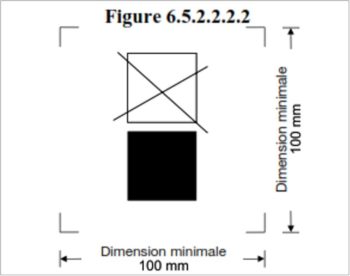

As our IBCs are not intended to be stacked, they also bear the following mark:

c. Installation of the IBC on the trailer

The IBC is mechanically attached to the trailer with bolts.

d. Periodic inspection of the IBC

Frequency of periodic inspections: every 2.5 and 5 years (§4.1.2.2 of the ADR)

Every metal, rigid plastics or composite IBC shall be subjected to the appropriate inspections and tests in accordance with 6.5.4.4 or 6.5.4.5 of ADR:

- Before it is put into service;

- Thereafter at intervals of not more than two and a half and five years, as appropriate;

- After repair or reconstruction, before it is reused for transport.

An IBC shall not be filled and presented for carriage after the expiry date of the validity of the last periodic test or inspection. However, an IBC filled before the expiry date of the validity of the last periodic test or inspection may be carried for a maximum of three months after that date. In addition, an IBC may be carried after the expiry date of the last periodic test or inspection:

a) after it has been drained but before it has been cleaned to undergo the prescribed test or inspection before being refilled;

b) unless an exemption is granted by the competent authority, for a period of not more than six months after the date of expiry of the validity of the last periodic test or inspection to allow the return of the dangerous goods or residues for proper disposal or recycling.

All metal IBCs, rigid plastic IBCs or composite IBCs must be inspected to the satisfaction of the competent authority (e.g. CeFEA):

Inspection and test every 5 years (§6.5.4.4.1 of the ADR) :

a) before it is brought into service (including after reconstruction), and thereafter at intervals of not more than five years, in respect of :

- Conformity to the design type, including markings;

- The internal and external condition;

- The proper functioning of the service equipment;

Removal of insulation, if present, is only necessary if it is required for a proper examination of the IBC body;

Inspection and testing every 2.5 years (§6.5.4.4.1) :

b) at intervals of not more than two and a half years, in respect of:

- the external state ;

- the proper functioning of the service equipment;

Removal of insulation, if present, is only necessary if it is required for a proper examination of the IBC body.

Each IBC shall conform in all respects to the design type to which it refers.

e. Marking/Labelling of the IBC

Any IBC which contains or has contained oil must be marked and labelled during transport with the following to identify the oil and the hazard:

- UN number of the oil preceded by the letters UN (minimum font size 12 mm high)

- Environmentally hazardous” mark (diamond format 100 x 100 mm)

- Class 3 hazard label (100 x 100 mm diamond format, flame in black or white)

These marks and labels must be on one side of the IBC or on both sides of the IBC if it has a capacity of more than 450 litres.

a. Principles of the exemption

ADR stipulates in §1.1.3 that under certain conditions, partial or total exemptions may apply:

In the case of some of our trailers, the exemption related to the quantities transported per transport unit, provided for in §1.1.3.6, is applicable.

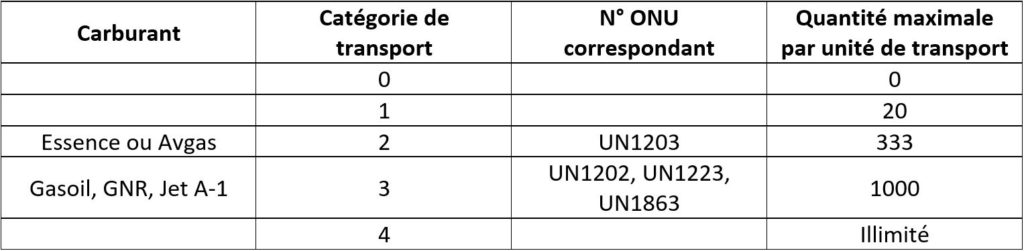

Some chapters of the ADR do not apply when hydrocarbons are carried in a single transport unit that does not exceed a threshold depending on the class of hydrocarbon:

Where this threshold is not exceeded, a lighter version of the ADR applies. The following requirements do not apply:

- Chapter 1.10;

- Chapter 5.3;

- Section 5.4.3;

- Chapter 7.2 except V5 and V8 under 7.2.4;

- CV1 under 7.5.11;

- Partie 8 except :

- 8.1.2.1 a);

- 8.1.4.2 à 8.1.4.5;

- 8.2.3;

- 8.3.3;

- 8.3.4;

- 8.3.5;

- Chapter 8.4;

- S1(3) and (6);

- S2(1);

- S4; S5;

- S14 à S21;

- S24 of chapter 8.5;

- Part 9.

The total exemption applies to all trailers transporting fuels for refuelling on site (cf. §1.1.3.1.c of the ADR) where the capacity of a package (IBC) does not exceed 320L for petrol or avgas and 450L for diesel or paraffin. In this case, the application of the TDG Order is not necessary.

The partial exemption applies to all trailers transporting fuels with a capacity not exceeding 320L for petrol or avgas and 1000L for paraffin or diesel. In this case the TDG Order is applicable.

b. Equipment

Fire extinguishing means (§8.1.4.2 of the ADR)

Dangerous goods transport units exempted according to 1.1.3.6 must be equipped with a 2kg fire extinguisher. The extinguisher must be approved, sealed and checked annually.

Equipotential bonding (§4.1.2.1 of the ADR)

When IBCs are used for the transport of liquids with a flash point not exceeding 60°C (in a closed crucible) or powders likely to cause dust explosions, measures must be taken to avoid any dangerous electrostatic discharge.

The trailers concerned are equipped with an equipotential bonding reel to ensure electrostatic discharge.

c. Document

Transport documents (§8.1.2.1 of the ADR)

The transport document provided for in §5.4.1 of the ADR identifying all the dangerous goods transported is obligatory on board the vehicle.

However, if the transport is carried out under the thresholds of §1.1.3.6 of the ADR, only on national territory and on own account, this transport document is optional

d. Training

User training (§8.2.3 of the ADR)

All persons whose duties relate to the carriage of dangerous goods by road must have received training in accordance with Chapter 1.3 on the provisions governing the carriage of such goods, appropriate to their responsibilities and duties. This requirement applies, for example, to personnel employed by the oil carrier or consignor, personnel loading and unloading dangerous goods, personnel working for freight forwarders and shippers and drivers of vehicles, other than those holding a certificate in accordance with 8.2.1, engaged in the carriage of dangerous goods by road.

e. Signage on the transport unit

No marking is required on the transport unit (front of the vehicle and rear of the trailer)

a. Equipment

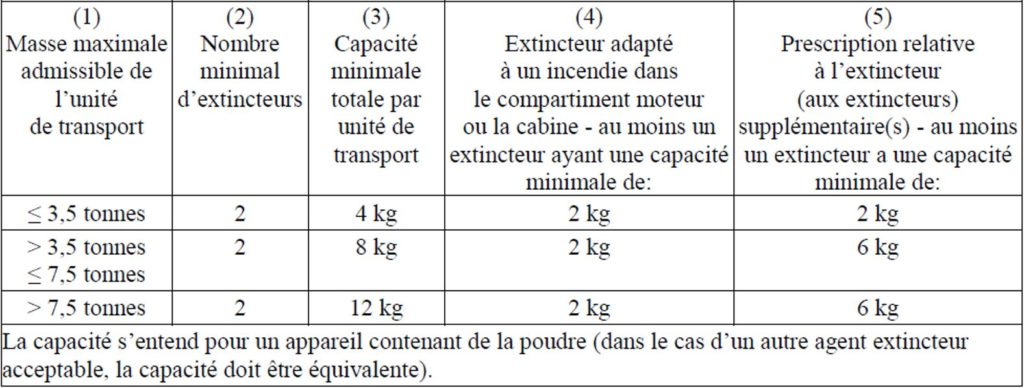

Fire extinguishing means (§8.1.4.2 of the ADR)

Transport units carrying dangerous goods must be equipped with fire extinguishers:

Fire extinguishers must be approved, sealed and checked every year

Equipotential bonding (§4.1.2.1 of the ADR)

When IBCs are used for the transport of liquids with a flash point not exceeding 60 °C (in closed crucibles) or powders likely to cause dust explosions, measures must be taken to avoid any dangerous electrostatic discharge.

The trailers concerned are equipped with an equipotential bonding reel to ensure electrostatic discharge.

Miscellaneous equipment and personal protective equipment (§8.1.5.2 of the ADR)

Each transport unit must have the following equipment on board:

- One wheel chock per vehicle, of dimensions appropriate to the maximum mass of the vehicle and the diameter of the wheels;

- Two self-supporting warning signs;

- Eyewash ;

For each member of the crew :

- A fluorescent harness;

- A non-metallic portable lighting device;

- A pair of protective gloves;

- Eye protection equipment.

Additional equipment required for the transport of fuel:

- A shovel

- A manhole cover

- A collection tank

b. Document

Transport documents (§8.1.2.1 of the ADR)

The transport document provided for in 5.4.1 identifying all the dangerous goods transported is mandatory on board the transport unit.

c. Training

User training (§8.2.3 of the ADR)

All persons whose duties relate to the carriage of dangerous goods by road shall have received training in accordance with Chapter 1.3 on the provisions governing the carriage of such goods, appropriate to their responsibilities and duties. This requirement applies, for example, to personnel employed by the carrier or consignor, personnel loading and unloading dangerous goods, personnel working for freight forwarders and shippers and drivers of vehicles, other than those holding a certificate in accordance with 8.2.1, involved in the carriage of dangerous goods by road.

Driver training (§8.2 of the ADR)

Drivers of vehicles carrying dangerous goods must hold a certificate issued by the competent authority stating that they have undergone training and passed an examination on the special requirements to be met when carrying dangerous goods. Each driver must, as a minimum, hold the basic certificate. There are additional specialisations (explosive, radioactive and tank) which are not necessary for the transport of our trailers.

d. Signage of the transport unit

Orange marking (§5.3 of the ADR)

As our tanks are IBCs, and therefore packages in the sense of the regulations, the orange signs to be affixed during transport must be blank. Two of them must be fixed to the front and rear of the vehicle with fire-resistant fixings.

Specifications of the orange panels :

The orange signs must be retro-reflective and have a base of 40 cm and a height of 30 cm; they must have a black border of 15 mm. The material used must be weather resistant and guarantee a durable sign. The sign must not come loose from its mounting after a 15 minute fire. It must remain in place regardless of the orientation of the vehicle. Orange signs may have a horizontal black line in the middle with a line width of 15 mm.

If the size and construction of the vehicle is such that there is insufficient space to attach these orange panels, their dimensions may be reduced to a minimum of 300 mm for the base, 120 mm for the height and 10 mm for the black line.

The TDG Order is applicable to operations involving the delivery of fuel for combustion engines during transport.

In this case, several measures must be put in place on the trailer to adapt to appendix IV.10 of the TDG decree:- The trailer must be careened (§3.1.2)

– Forced ventilation must be installed or top and bottom ventilation (§3.1.3)

– The ADR suitcase is mandatory (§4.4)

– ADR training with the speciality “petroleum products” is mandatory for the driver (§8)

– For UN1203 and UN3475, the vapour recovery system is mandatory (§4.2)

– A fire extinguishing system

External sources

Also discover the regulations relating to the storage of hydrocarbons and the trailer license and registration.